Identification Solutions for reliable data acquisition(I)

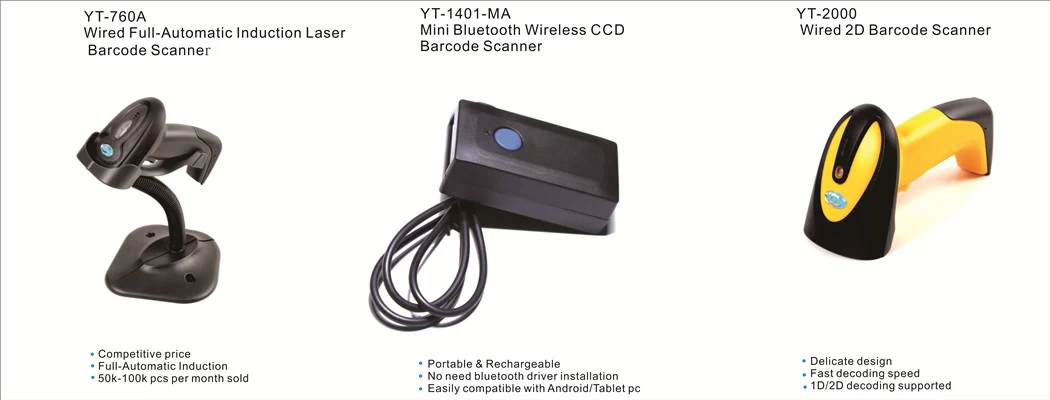

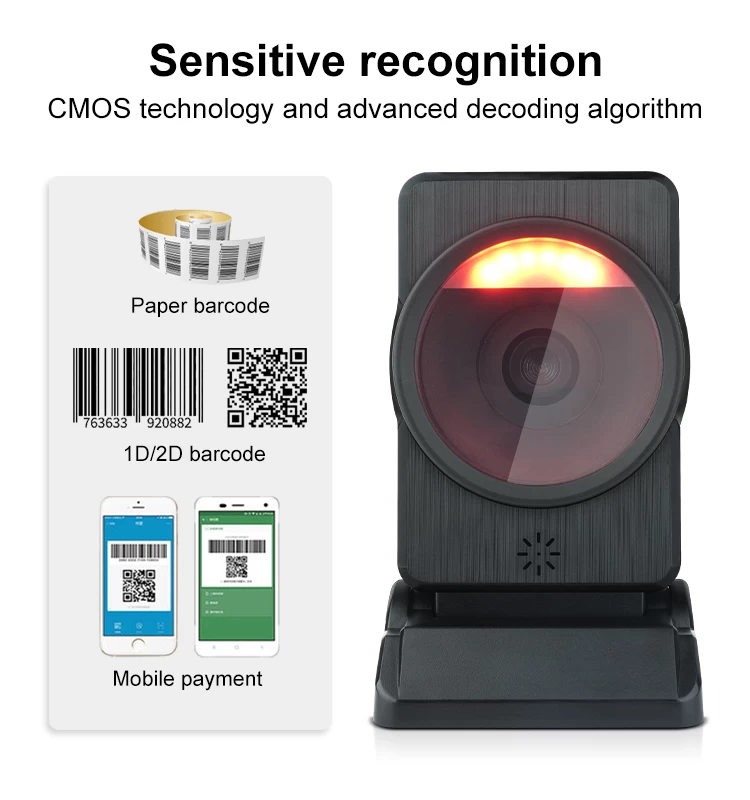

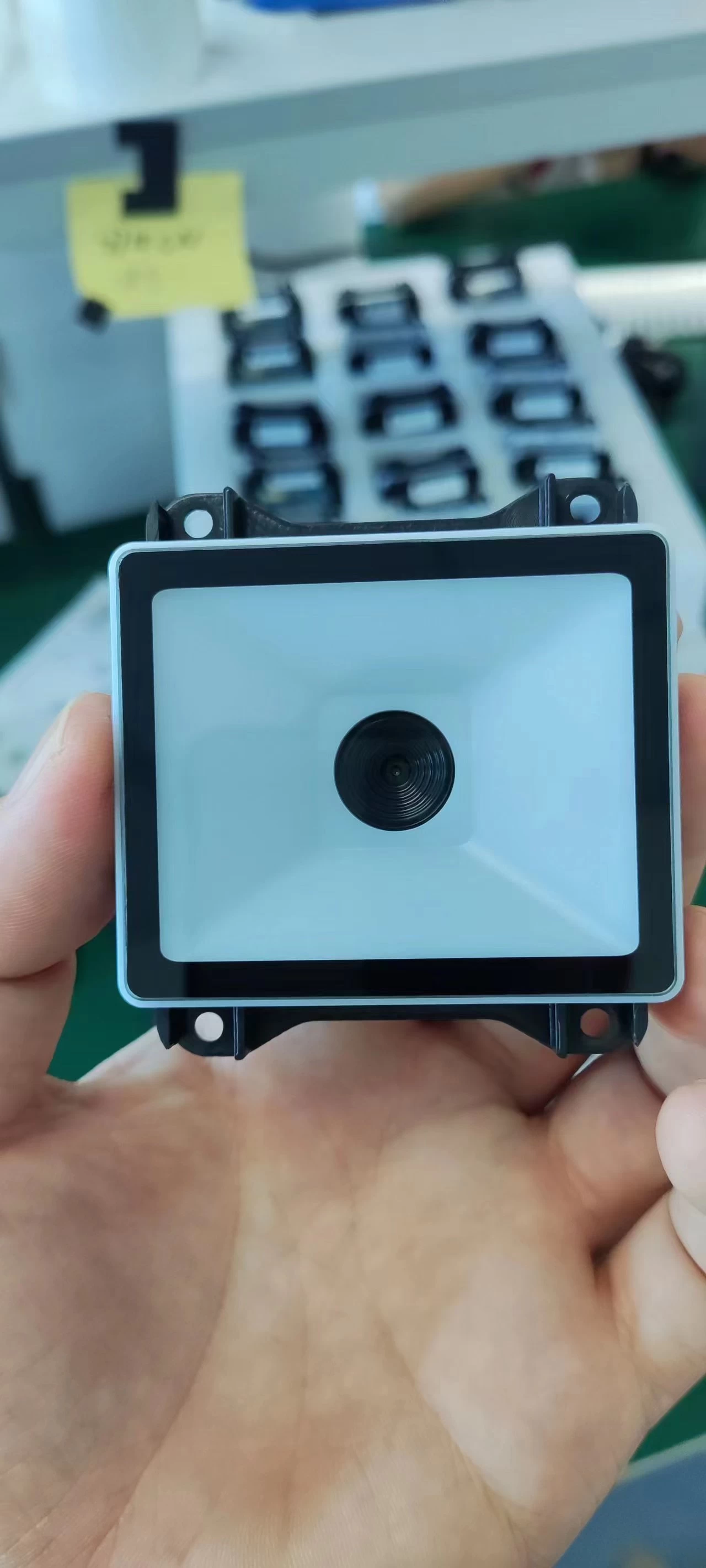

Laser-based barcode scanning

Identifying products by barcode

The barcode is the oldest of the product identification data carriers, and it has been widely used in industry and trade since the 1970s. Nearly every consumer good is labelled with the EAN-13 barcode, which is valid all over the world and which encodes the GTIN (Global Trade Item Number), a globally standardised part number.

Thanks to barcodes, food is now labelled uniquely, reduced process errors have led to a higher degree of safety, warehousing can be automated, it is easier to move goods and, most importantly, products can be read incredibly quickly using laser scanners. If a product is recalled, the automated identification of the products involved and their distribution channels makes it possible to speed up all of the necessary measures. Giving each product a unique mark also has an impact on production, as the items have to be marked, read, verified and saved in the production line.

The Australian distribution centre of a large food company takes in 10,000 pallets each day, each of which is about 2 m high and loaded with different products, which are all provided with their own barcode. If a product is labelled incorrectly, this could mean that the wrong item is delivered and could make it extremely difficult to trace. Similarly, food that is not labelled correctly can trigger foodborne illness. An error rate of 2% would mean that 73,000 pallets would have to be taken apart, manually processed and inspected each year.