Barcode Scanners and Scanning Technologies

Ben

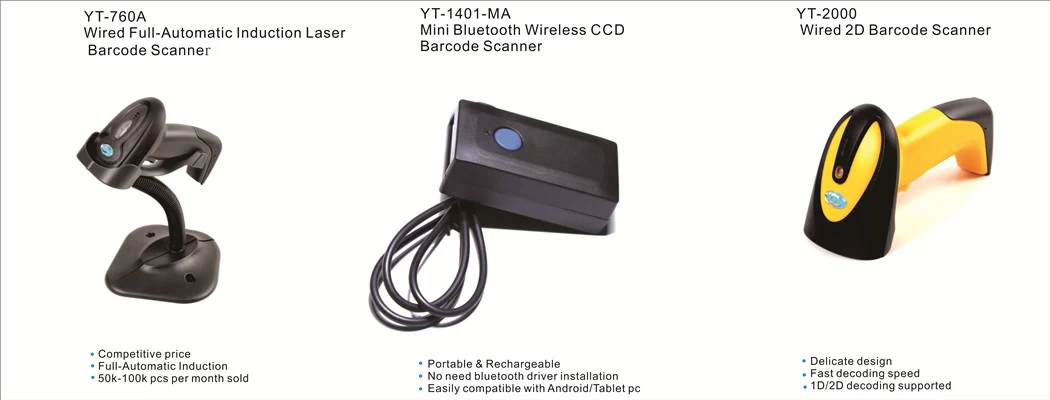

Yumite

2016-12-26 13:32:33

Barcode Scanners and Scanning Technologies

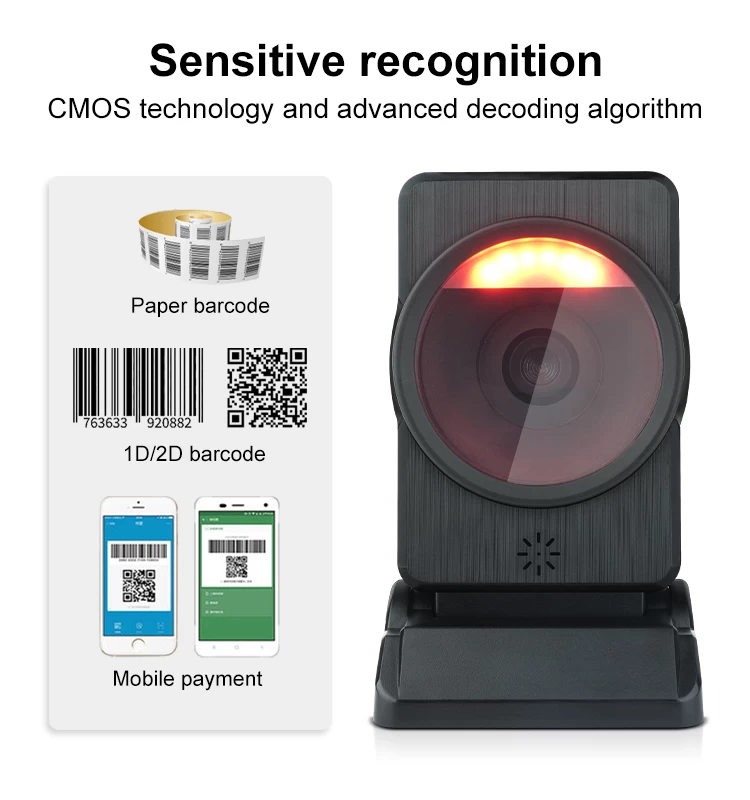

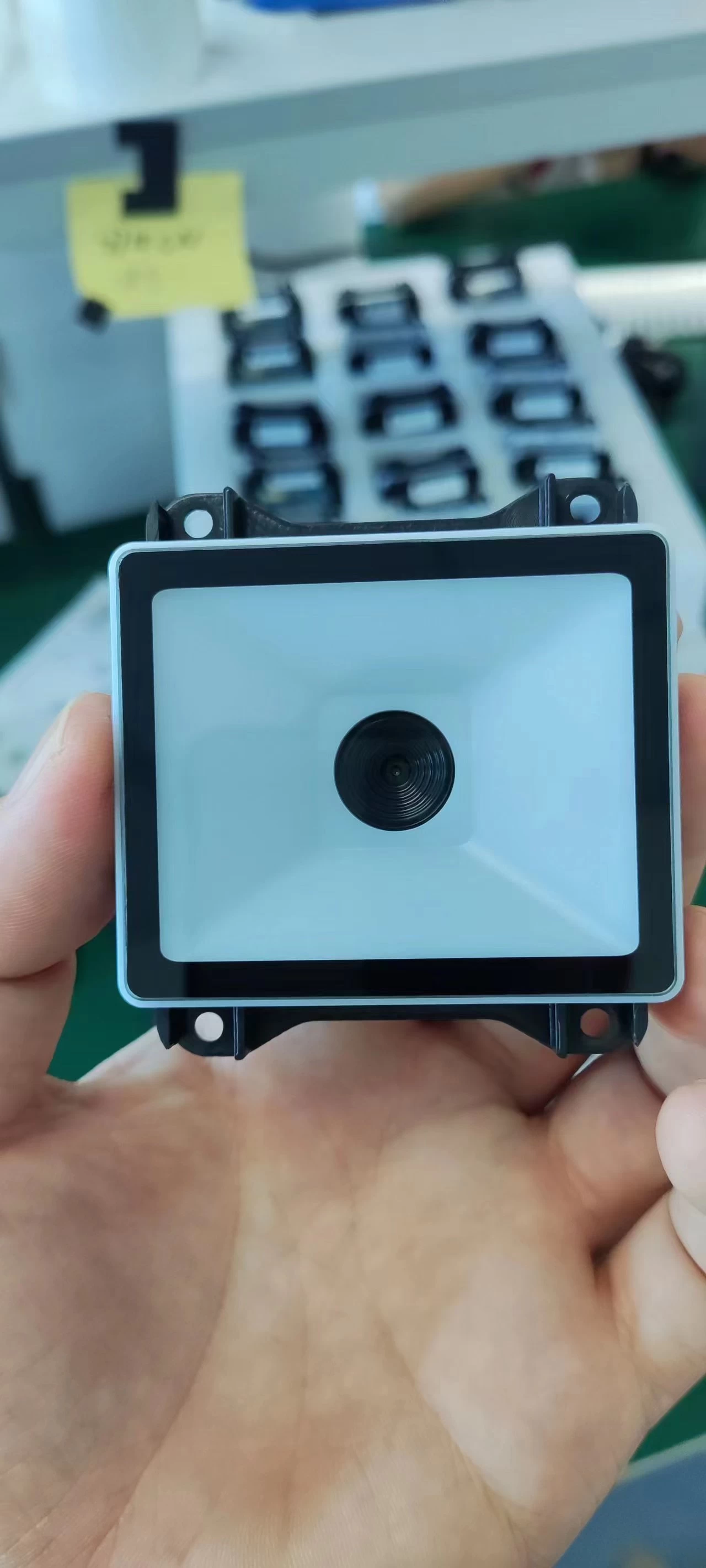

CCD

CCD scanners do not have to be in direct contact with the surface of the barcode, but their depth of focus is somewhat limited. Most CCD scanners have a working range from roughly 0.25 in (6.35 mm) to 1.0 in (25.4 mm); there are some products available with a slightly greater range. The width of the CCD sensor array in the scanner limits the maximum width of a barcode that can be scanned; if the barcode is wider than the scanner, it cannot be read.

Laser

Laser scanners use a moving pinpoint of light to illuminate the barcode, and a single photocell receives the reflected light. Most laser scanners sweep the laser beam horizontally using an electronically controlled mirror. Laser scanners tend to be quick and precise and can often read denser barcodes than other technologies. A primary advantage of a laser scanner is depth of focus; since a laser beam diverges very little with distance, scanners of this type generally have a working range from roughly 1 in (2.54 cm) to 12 in (30.48 cm). By increasing laser power and narrowing the angle of beam sweep special long-range scanners can read at ranges as long as to 30 to 40 feet (9 to 12 m). Since the laser beam is swept horizontally at a fixed angle, the length of the scan line on the target increases as the distance increases; if a barcode is too wide for the laser beam, just back up a little bit.

2-dimensional laser scanners sweep the beam horizontally and vertically at the same time, creating a raster pattern. This type of scanner is used to read 2-dimensional barcodes like PDF-417.

Interlocking pattern scanners use mirrors to create a grid of scan lines. This is the type of scanner most often used in grocery store checkout lines, and the advantage is that when a barcode passes the scanner the chances are good that at least one of the scan lines will get a clean cross section of the barcode; the operator does not have to aim the scanner or carefully position the barcode. The result is faster overall operation. One characteristic of scanners of this type is that the optics can be designed to make it appear as though laser beams are originating from different points (it is all done with mirrors; there is only one laser). This gives the scanner the ability to wrap the scan pattern around corners on the target; the greater the separation between points of origin the greater the wrapping effect (and the larger the size of the scanner's faceplate).

Some interlocking pattern scanners use a rotating holographic disk instead of mirrors to aim the laser beam. This type of scanner is often mounted above fast-moving conveyor belts to read barcodes on packages. With a large faceplate area, the wrap-around effect makes it possible to see barcodes whether they are on the leading side, top, or trailing side of the package. Depending on the size of the scanner and the boxes it may even be possible to read barcodes on the sides of the boxes.

CCD

CCD scanners do not have to be in direct contact with the surface of the barcode, but their depth of focus is somewhat limited. Most CCD scanners have a working range from roughly 0.25 in (6.35 mm) to 1.0 in (25.4 mm); there are some products available with a slightly greater range. The width of the CCD sensor array in the scanner limits the maximum width of a barcode that can be scanned; if the barcode is wider than the scanner, it cannot be read.

Laser

Laser scanners use a moving pinpoint of light to illuminate the barcode, and a single photocell receives the reflected light. Most laser scanners sweep the laser beam horizontally using an electronically controlled mirror. Laser scanners tend to be quick and precise and can often read denser barcodes than other technologies. A primary advantage of a laser scanner is depth of focus; since a laser beam diverges very little with distance, scanners of this type generally have a working range from roughly 1 in (2.54 cm) to 12 in (30.48 cm). By increasing laser power and narrowing the angle of beam sweep special long-range scanners can read at ranges as long as to 30 to 40 feet (9 to 12 m). Since the laser beam is swept horizontally at a fixed angle, the length of the scan line on the target increases as the distance increases; if a barcode is too wide for the laser beam, just back up a little bit.

2-dimensional laser scanners sweep the beam horizontally and vertically at the same time, creating a raster pattern. This type of scanner is used to read 2-dimensional barcodes like PDF-417.

Interlocking pattern scanners use mirrors to create a grid of scan lines. This is the type of scanner most often used in grocery store checkout lines, and the advantage is that when a barcode passes the scanner the chances are good that at least one of the scan lines will get a clean cross section of the barcode; the operator does not have to aim the scanner or carefully position the barcode. The result is faster overall operation. One characteristic of scanners of this type is that the optics can be designed to make it appear as though laser beams are originating from different points (it is all done with mirrors; there is only one laser). This gives the scanner the ability to wrap the scan pattern around corners on the target; the greater the separation between points of origin the greater the wrapping effect (and the larger the size of the scanner's faceplate).

Some interlocking pattern scanners use a rotating holographic disk instead of mirrors to aim the laser beam. This type of scanner is often mounted above fast-moving conveyor belts to read barcodes on packages. With a large faceplate area, the wrap-around effect makes it possible to see barcodes whether they are on the leading side, top, or trailing side of the package. Depending on the size of the scanner and the boxes it may even be possible to read barcodes on the sides of the boxes.