Identification Solutions for reliable data acquisition(III)

Identification in the second dimension

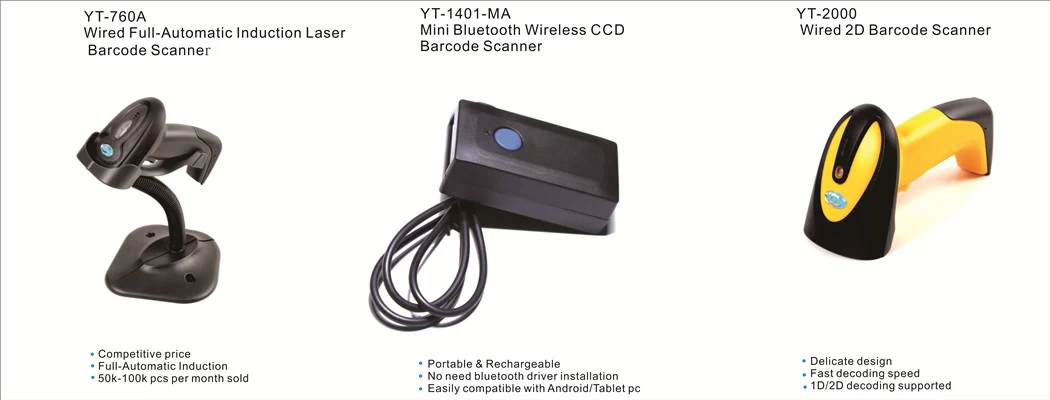

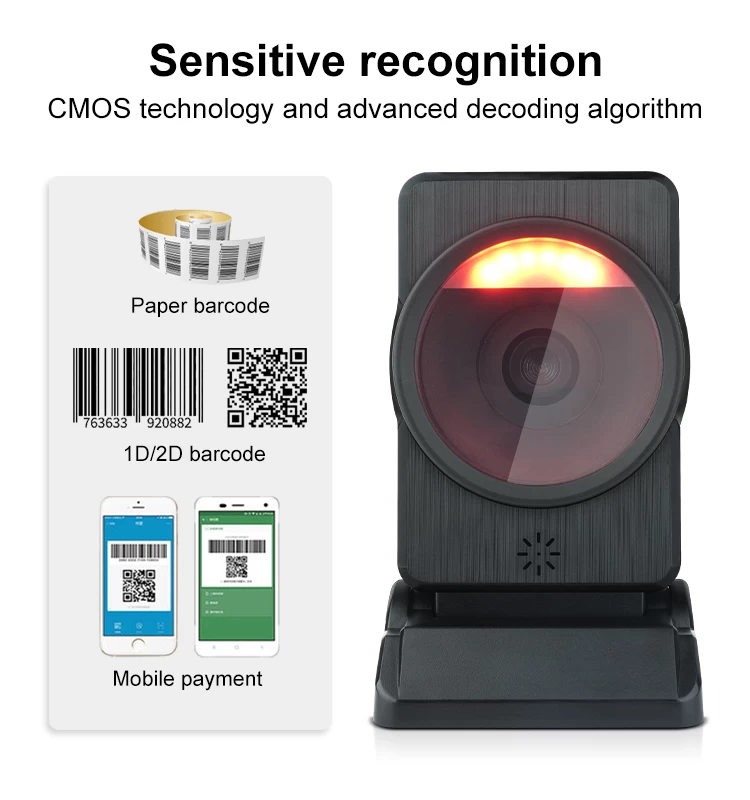

Alongside the traditional barcode, the food industry also uses 2D codes to ensure traceability and process reliability. While barcodes only code data in a single dimension, 2D codes map data in symbols, in a two-dimensional area that provides higher information density.

The data from a 2D code can be read using image-based code readers and processed further electronically. In the food industry, the use of data matrix codes is most common in intralogistical and packaging processes. QR (quick response) codes, are used on food packaging for mobile tagging so that consumers can trace a product with ease.

In the European Union, foodstuffs must be marked with a best-before date. In Germany, the Batch Marking Regulation also applies, requiring all foodstuffs to be provided with a batch number assigning the product to a production run. Both the best-before date and the batch number are marked on the product in plain text. Image-based code readers read barcodes, 2D codes and plain text automatically, shorten the processing times and therefore increase productivity.

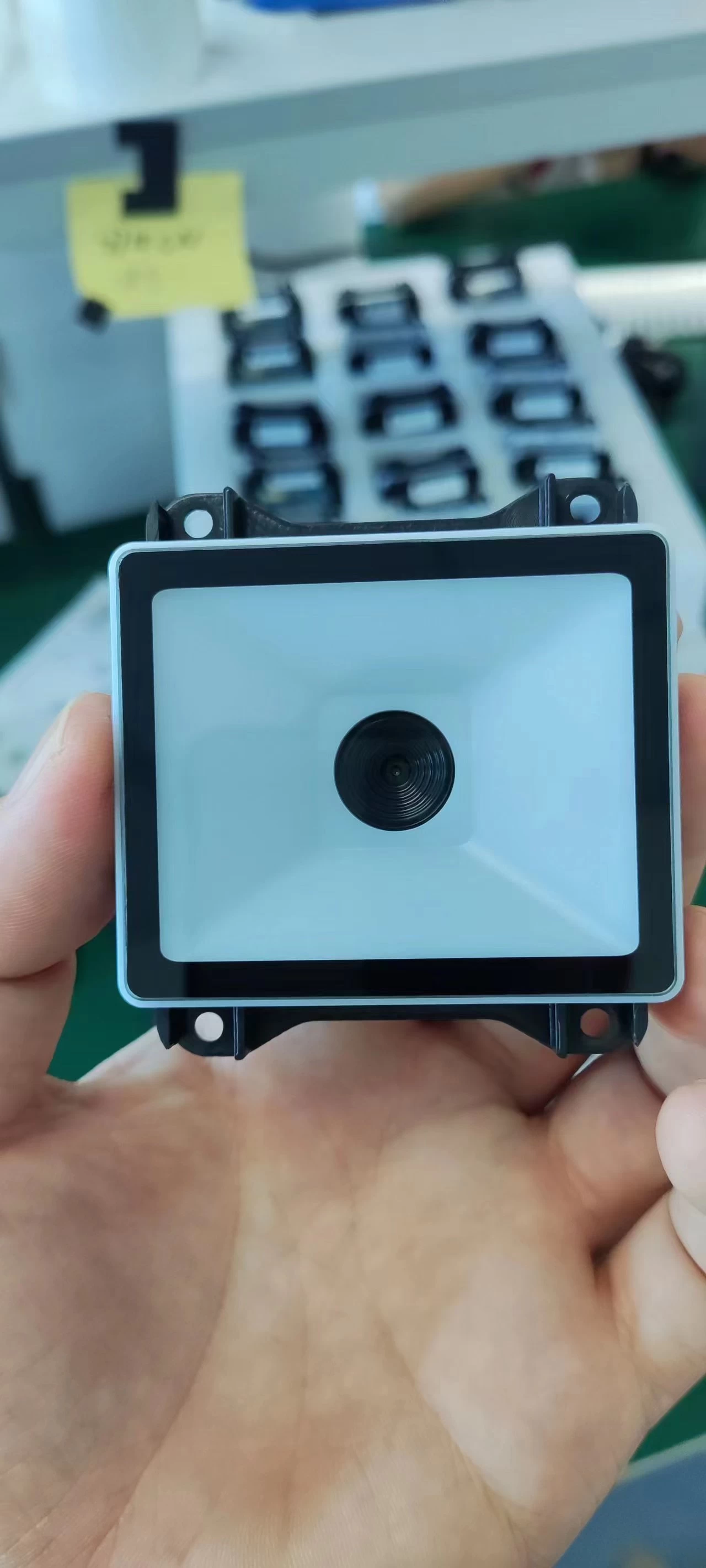

Flexible, compact and well connected

The Lector62x image-based code reader from SICK is highly flexible. Using various image processing algorithms, it reliably identifies all types of codes used in the food industry, including barcodes (1D), Data Matrix and QR codes (2D), as well as plain text. The Lector620 High Speed variant reads codes at speeds of up to 6 m/s. Live images make it possible to analyse the code quality and reading performance, and images can also be saved for data archiving purposes.